Re: Got Wood?

|

Joined: Jun 2003

Posts: 8,488

axiomite

|

axiomite

Joined: Jun 2003

Posts: 8,488 |

Right on, Bob!! The Abyss! You Go!

bibere usque ad hilaritatem

|

|

|

Re: Got Wood?

|

Joined: Mar 2010

Posts: 3,596 Likes: 1

connoisseur

|

connoisseur

Joined: Mar 2010

Posts: 3,596 Likes: 1 |

Do you think we'll hear from him again tonight, Tom? Hate to think of him up all night, stuck in his shop 'cause he slipped on and fell in the contact cement.

Always call the place you live a house. When you're old, everyone else will call it a home.

|

|

|

Re: Got Wood?

|

Joined: Jun 2003

Posts: 8,488

axiomite

|

axiomite

Joined: Jun 2003

Posts: 8,488 |

I'm not worried about any glue mishaps. Only Michael can contain Michael. But I'm not waiting up.

bibere usque ad hilaritatem

|

|

|

Re: Got Wood?

|

Joined: Jul 2004

Posts: 4,444 Likes: 16

connoisseur

|

connoisseur

Joined: Jul 2004

Posts: 4,444 Likes: 16 |

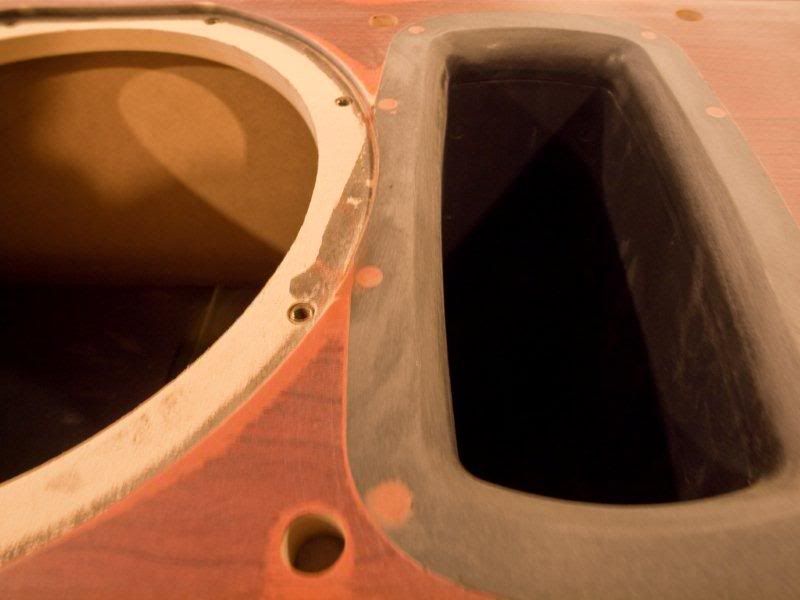

Waiting for the back glue to dry to stick the back down. With I would have done that first, dangit. But....so far so good. I'm documetning my adventure. So much for my tempate idea...... Didn't work. Had to cut the holes by hand.

|

|

|

Re: Got Wood?

|

Joined: Mar 2010

Posts: 3,596 Likes: 1

connoisseur

|

connoisseur

Joined: Mar 2010

Posts: 3,596 Likes: 1 |

Had to check on your progress. Knew you'd get it all to bend to your will. And I didn't want to add confusion, but I would have hand cut the veneer out of the driver holes anyway. You're doin' it. Good luck with next phase, Michael.

And remember... this is soooo much bigger than you now ;-)

Always call the place you live a house. When you're old, everyone else will call it a home.

|

|

|

Re: Got Wood?

|

Joined: Jul 2004

Posts: 4,444 Likes: 16

connoisseur

|

connoisseur

Joined: Jul 2004

Posts: 4,444 Likes: 16 |

Just waiting for the Poly to dry now. I tried some poly spray in a can this time. Don’t think I like that crap much, but I can’t brush gloss to save my life, so it did come out better than what my brush skills would have accomplished. Should be able to buff it with some beeswax tomorrow and put it back together. I hate finishing….. I took a few pics throughout the process so I can put together a step by step tutorial. Maybe tomorrow if I have time.

|

|

|

Re: Got Wood?

|

Joined: Mar 2010

Posts: 3,596 Likes: 1

connoisseur

|

connoisseur

Joined: Mar 2010

Posts: 3,596 Likes: 1 |

Very much looking forward to your final result. Sure they'll look great.

Always call the place you live a house. When you're old, everyone else will call it a home.

|

|

|

Re: Got Wood?

|

Joined: Jul 2004

Posts: 4,444 Likes: 16

connoisseur

|

connoisseur

Joined: Jul 2004

Posts: 4,444 Likes: 16 |

I don’t have much spare time, so I’ll make this brief. If anyone wants to try this and has specific questions, I’ll answer them as they come up. I used paper backed cherry veneer. It’s .018” thick, so I’m guessing it’s 20 mil. You can get 10 or 20 mil. I chose this species to match the cabinets in my kitchen which is part of the great room where the 600 is going. I wasn’t sure if the veneer would roll over the leading edge corners without cracking, so I rounded them down a bit. I used a random orbital sander with 150 grit paper. I then used a sanding block to make sure that whatever radius I ended up with would be consistent from top to bottom.  The port will not come out without destroying it. It is flanged at both ends and there’s no way to get it out without cutting it in half. I decided to sand it down flush with the cabinet. I ran some sheet rock screws in to secure it, and then filled them with filler.  Because I wanted to roll the corners, I needed a total veneer width of 47 ¾”. The sheet is 48 ½”, so it was important to set it just right. Once the veneer touches the case, there’d be no moving it with destroying it. Contact cement sticks like crazy. I used a water based cement made by 3M. It worked very well. I rolled it on to the veneer and the case with a 4” foam roller, let it sit for about 30 to let it dry, then prepared to adhere it. I also marked the center of the case leading edge and the center of the veneer to position it. This veneer is much more pliable than I thought it would be, so I had to use a bunch of spacers to keep it from sagging and touching the case before I wanted it to. I used a 2” laminate roller, starting in the center of the sheet of the leading edge and worked my way out. After the leading edge was secure and flat, I just rolled it around the corners, pressing it down with my hand then following up with the roller.

|

|

|

Re: Got Wood?

|

Joined: Jul 2004

Posts: 4,444 Likes: 16

connoisseur

|

connoisseur

Joined: Jul 2004

Posts: 4,444 Likes: 16 |

|

|

|

Re: Got Wood?

|

Joined: Jul 2004

Posts: 4,444 Likes: 16

connoisseur

|

connoisseur

Joined: Jul 2004

Posts: 4,444 Likes: 16 |

|

|

|

|

Forums16

Topics24,945

Posts442,489

Members15,617

| |

Most Online2,082

Jan 22nd, 2020

|

|

|

0 members (),

1,124

guests, and

3

robots. |

|

Key:

Admin,

Global Mod,

Mod

|

|

|

|